AEROSPACE

We’re Taking Off

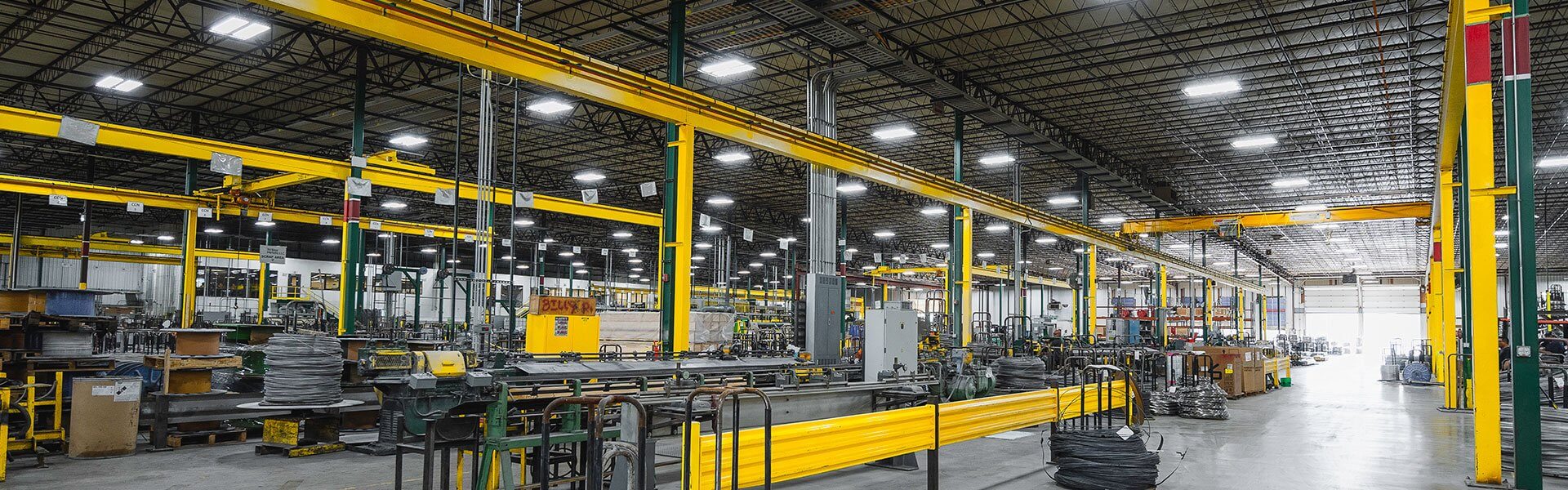

When we purchased Pinnacle Metals in 2009, we had the vision of becoming a world class supplier into the aerospace market. We were already capable of producing key alloys such as A286, 718, and 17-4, but there was a lot more work to be done. Over the last 10 years, we have focused on continuous improvement by investing in state of the art equipment at every stage of our production process. This includes North America’s most modern back die shaver, strand copper / moly coating technology for the ultimate coating consistency, a new AMS 2750 certified batch anneal furnace with in line water quenching, and a new shot blast line to provide a beautiful, texturized surface for our aerospace wire products. These investments have enabled us to bolster our capacity, improve our quality, and reduce our cost structure through unparalleled production efficiency. We secured our AS9100 certification in July 2017 and have built sizable inventories of nickel alloy, stainless, and aluminum bar and wire to service the aerospace fastener manufacturing community.