PRODUCTS

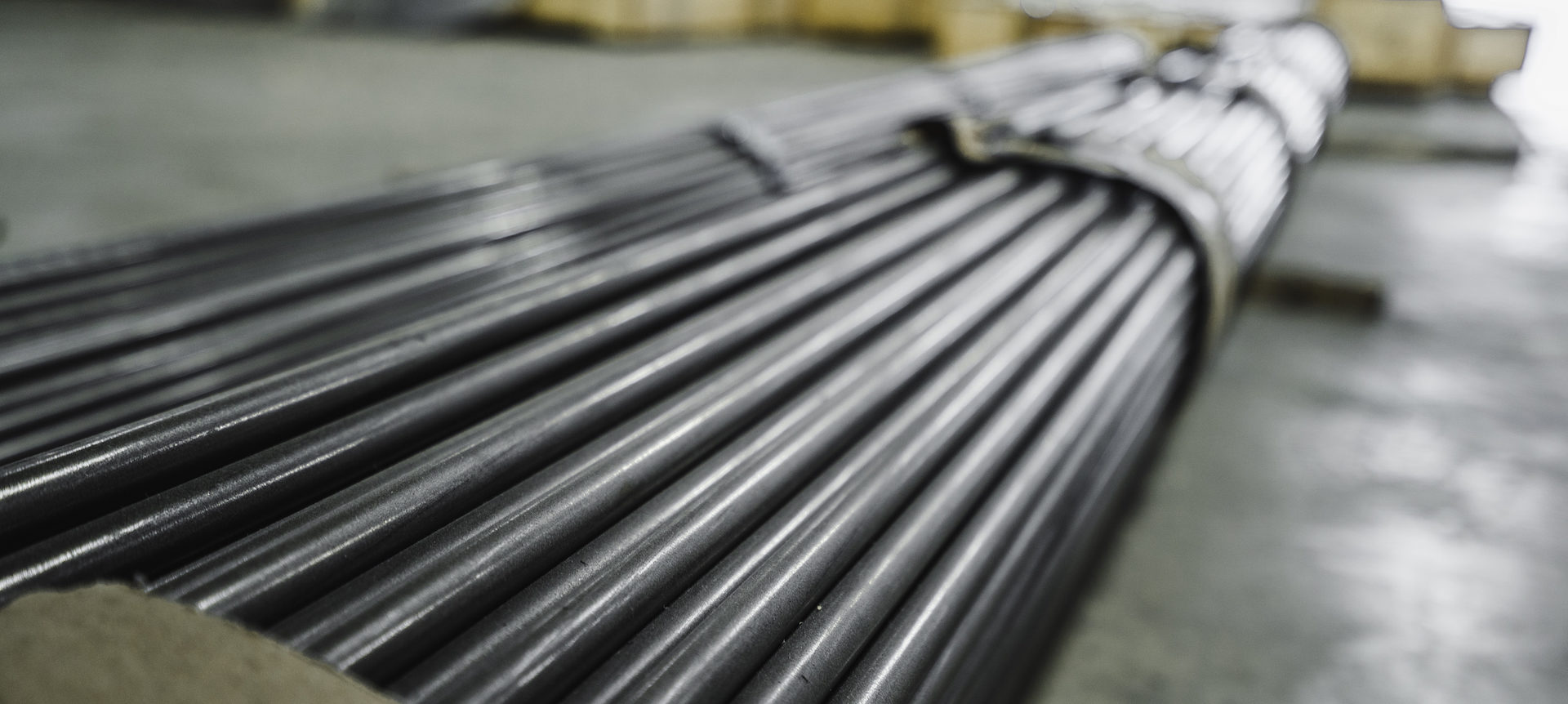

Nickel Alloy Bar

Tri Star Metals is committed to servicing the nickel alloy bar market. We carry a robust raw material inventory in a large variety of alloys, including Hastalloys, Inconels and Monels. This enables us to immediately go to production and make a customized product (diameter / length / mechanical properties) with the fastest lead times in the industry. Almost all nickel bar supplied is DFARS compliant and ground to final size for a clean surface finish. While traditional mills typically require minimum production runs ranging from 2000-6000 #, for most alloys we can offer a 250 # minimum production run to help our customers capture business without over-committing to inventory. To better support our aerospace machining partners, we have positioned expansive inventories of 718 and A286 bar in our Phoenix stocking facility.

HIGH % NICKEL ALLOYS

| Common Applications: Electronics, Synthetic Fibers and Battery Applications | ||

| Nickel 200 | Nickel 205 | Nickel 99 |

| Nickel 201 | Nickel 61 | 95/5 Nickel Aluminum |

NICKEL – COPPER ALLOYS

| Common Applications: Marine Engineering, Chemical Processing Equipment, Valves, Fittings and Fasteners | |

| M400 | Alloy 60 |

| MR405 | Alloy 67 |

| MK500 | |

NICKEL – CHROMIUM ALLOYS

| Common Applications: Chloride-Ion Stress Corrosion, Chemical, Food Processing and Nuclear Engineering | |

| I600 | Alloy 22 |

| I601 | Alloy 82 |

| I625 | A80-20CB |

| I718 | C276 |

| X750 | HX |

NICKEL – IRON – CHROMIUM ALLOYS

| Common Applications: Higher Strength for Chemical Processing, Petrochemical Processing and Industrial Furnaces | |

| 330 | A286 |

| 35-19CB | IN800 |

| Alloy 20 | IN825 |

PRODUCTION CAPABILITIES

| Cold Drawn Wire | Annealed Wire | Cold Drawn Bar | |

|---|---|---|---|

| Size | .032 – .3124″ | 032 – .280″ | .0625 – .105″ |

| .3125 – .499″ | .106 – .250″ | ||

| .500 – .875″ | 251 – .500″ | ||

| – | .501 – .820″ | ||

| Diameter Tolerance | +/- .001″ | +/- .001″ | – |

| +/-.0015″ | |||

| +/- .002″ | |||

| Length | – | – | 4″ – 12′ |

| 12″ – 20′ | |||

| 12″ – 40′ | |||

| 36″ – 40′ | |||

| Length Tolerance | – | – | +/- 1/16″ |

| +/- 1/16″ | |||

| +/- 1/16″ | |||

| +/- 1″ |